Jeff Dunn, Glazerite UK Group’s Sales & Marketing Director, explains how their flush sash portfolio has evolved and continues to develop with market demand.

As a leading trade fabricator, market trends matter to us. Heritage styles are increasingly popular with consumers, and the way in which they can be manufactured is constantly evolving too. As a forward-thinking partner for our installers, it’s crucial we continually adapt our processes around product improvements, which is why Timberweld® caught our eye.

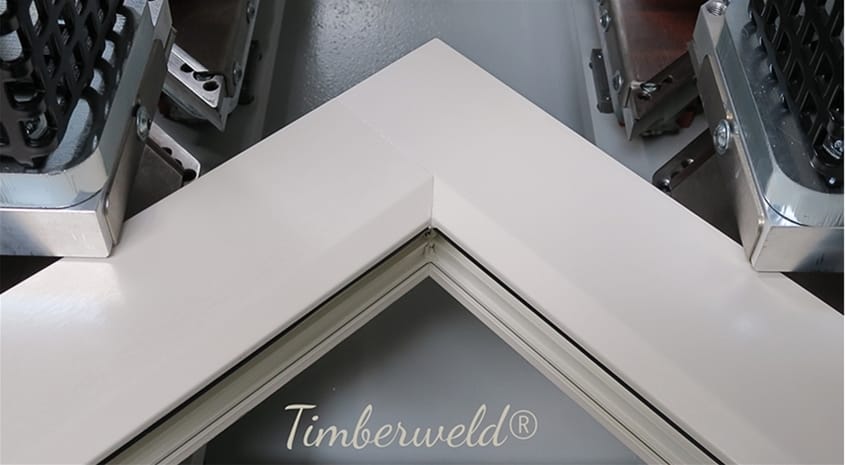

To meet market desire, we’ve invested further in our Specials Division in Wellingborough, Northamptonshire, which was set up in 2014 in recognition of the specialist machinery and techniques involved in fabricating heritage profiles. It’s here we manufacture both the UK-designed, UK-extruded Residence 9 and Residence 7 products, which are equally acclaimed by consumers and planning officers for their timber-like aesthetics. Part of our recent investment at the Specials Division has included the introduction of Timberweld, the patented method of welding corners on uPVC by butt welding sashes inside and out, replicating the authentic aesthetics delivered with a mechanical joint.

We’ve always been firm in our position to manufacture R9 windows via a mechanically jointed and glass bonded process. However, as technology and the market has developed, we now have a solution in Timberweld that enables us to offer the same structural integrity and security performance without the need for glass bonding. The ability to offer R9 unglazed offers installers a number of benefits, making it easier to fit, reducing handling and fitting costs and giving them the option to source glass from their own supplier. All of these contribute to a less complex installation, with scope for making higher margins further benefitting our customers.

In addition to the benefits for the homeowner and installer, the transition to using Timberweld also gives us flexibility in manufacture with the obvious efficiencies in the production process and logistics in the transportation.

Another heritage jewel in our portfolio is the Halo Flush Sash, which is manufactured at our East Division in Peterborough. We intend offering Timberweld across all of our flush sash options in the near future, but as this is a new concept for the Halo system we are still in the testing phase at present. Having three high performance flush sash products on offer gives our installer partners access to a solution for every customer budget, and allows them to take advantage of greater sales opportunities, as they never have to turn down a specialist, bespoke or non-standard job.

We like to give our installer partners everything they need to help them stand out amongst their own competitors, and in support of this we offer a full suite of heritage marketing materials including dropcards, point of sale materials and non-branded brochures, which they can use as their own, alongside the marketing assets and materials on offer from our suppliers.

The Residence Collection does a superb job of positioning and branding their products alongside high profile consumer brands such as Farrow and Ball. The aesthetics of both R9 and R7, combined with the acoustic, thermal and security benefits of the windows appeal to the consumer, along with the choice of colour palette, dual colour option and decorative beading to suit period and contemporary property refurbishment or new builds alike.

The Residence Collection does a superb job of positioning and branding their products alongside high profile consumer brands such as Farrow and Ball. The aesthetics of both R9 and R7, combined with the acoustic, thermal and security benefits of the windows appeal to the consumer, along with the choice of colour palette, dual colour option and decorative beading to suit period and contemporary property refurbishment or new builds alike.

As a fabricator, it matters to us that our customers’ customers are happy. Having a flush sash portfolio, which incorporates products at the forefront of innovation is vital. We back this up using cutting-edge fabrication techniques, broader added value business support offerings and exemplary customer service, so that we can continue on with our mission to give our installers a best-in-class experience.

So what’s next for our heritage portfolio? We have plans to continue investing in our capabilities and how we fabricate the products we offer so that we can continue to support our customers, while meeting the quality, authenticity and aesthetics their own customers expect. Watch this space…